We specialize in providing intelligent laser equipment and comprehensive industrial automation solutions. Our offerings include high-precision laser cutting machines, laser marking machines, laser welding machines, and more, all designed to meet the diverse needs of various industries. In addition to our standard laser equipment, we excel in delivering customized solutions tailored to the specific requirements of our clients. Whether it’s technical specifications, design aesthetics, functionality, accessories, or after-sales service, we offer personalized customization to ensure that our laser systems perfectly align with your operational needs.

Our laser systems are equipped with a range of laser heads with varying power capacities, offering different types of cutting, marking, and welding capabilities. Engineered with a focus on precision, efficiency, and reliability, these systems are perfectly suited to power the most demanding applications in industries like automotive, sheet metal processing, crafts manufacturing, and beyond, where excellence is not just expected but essential.

Our marking systems are equipped with top-tier lasers, including the MOPA M7 30W fiber laser, capable of marking a wide range of materials such as metal, plastic, glass, ceramics, and wood. These machines can effortlessly engrave patterns, text, barcodes, and other images with high precision. We offer a variety of laser marking machines in different models and styles to suit your needs, and we can also provide customized solutions tailored to your specific requirements.

The enclosed fiber laser marking machine offers everything you need for etching and engraving various metals, stones, and tiles.

Split fiber laser marking machine is our most compact fiber laser marking machine, offering a low-cost yet high-quality solution for businesses transitioning from traditional engraving, etching, and surface marking methods to laser technology.

This laser marking machine features an integrated design with a compact and small footprint, easy to install and operate, making it an ideal choice for a limited workspace.

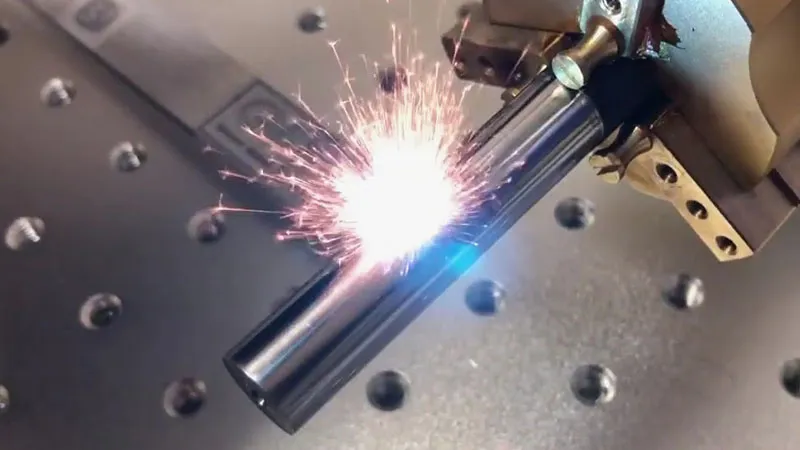

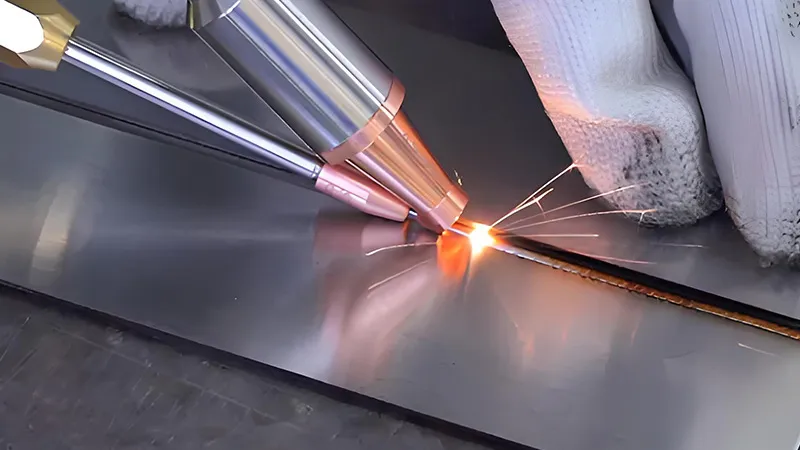

Laser welding is applicable to a wide range of metals and alloys, including carbon steel, stainless steel, zinc, copper, aluminum, chromium, and precious metals like gold and silver.

Compared to traditional welding machines, the EF-Hybrid laser welding machine features an integrated design with a built-in water chiller and laser source, offering powerful functionality in a compact space.

This 3-in-1 laser welding and cleaning machine is a versatile equipment that can cut, weld, and clean metal surfaces.

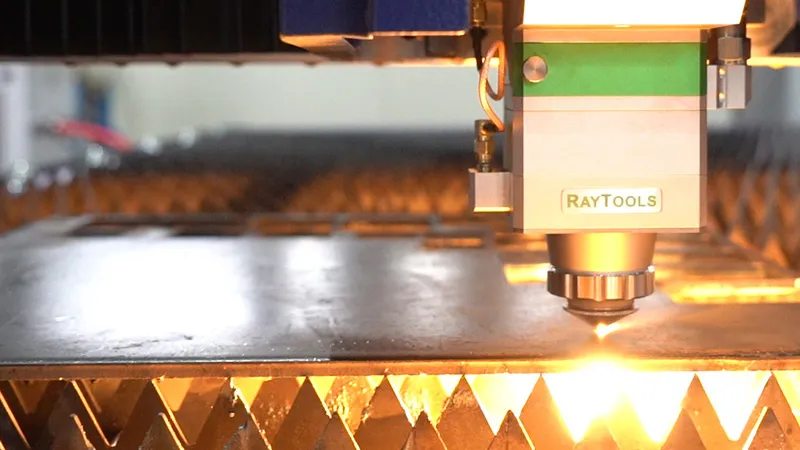

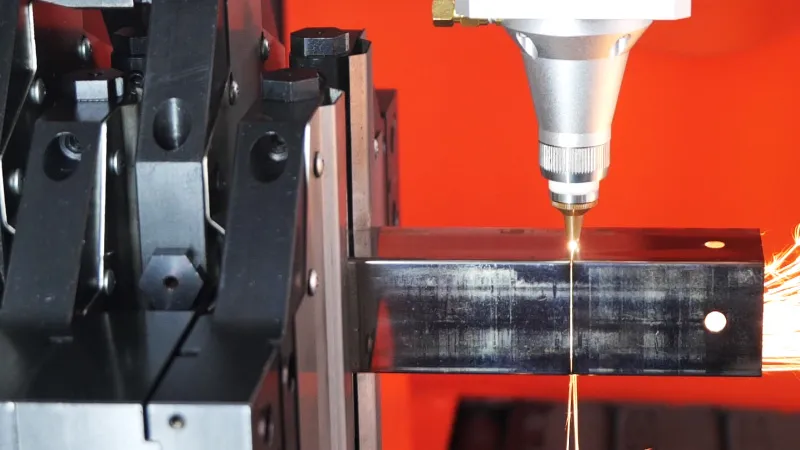

Our laser cutting systems primarily use two types of laser cutting heads, delivering high precision and speed across a variety of metals such as aluminum, steel, stainless steel, and copper, making them ideal for intricate designs and efficient industrial applications.

Open flatbed fiber laser cutting machine is an efficient thermal cutting process on metal sheets, offering positioning accuracy up to ±0.03mm, ensuring precise cuts and reducing material waste, and a maximum speed of 80,000mm/min.

This enclosed flatbed fiber laser cutting machine is specifically designed for high-speed cutting of various sheet metals.

The enclosed flatbed fiber laser cutting machine is designed for high-speed cutting of various metal sheets.

The high precision metal laser cutting machine offers an excellent customized solution for small-format,low-volume, high-precision processing of metal sheets and tubes.

This laser cutting machine features a dual-drive gantry system with a rail mounted gantry structure delivering high accuracy in large scale projects.

This is our largest general-purpose CO₂ laser machine, featuring a height-adjustable working area.

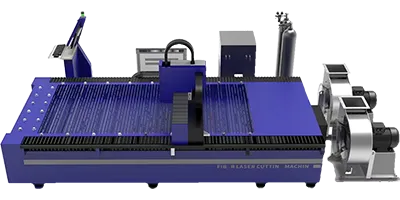

Our laser tube cutting system can be equipped with various fiber laser heads, allowing for the precise cutting of aluminum, stainless steel, and carbon steel workpieces. As laser technology continues to revolutionize design possibilities, more industries are turning to laser-cut tubes and profiles, driving a significant increase in demand. This system is widely used in industries such as kitchenware, lighting, automotive, fitness equipment, and hardware, where precision and efficiency are crucial.

This fiber laser tube cutting machine is a versatile and efficient tool designed for cutting and processing round tubes, square tubes, rectangular tubes, angle iron, channel steel, H-beams, and various other profiles.

The two-chuck laser cutting machine is a versatile tool for different metal working industries, designed for cutting and drilling square tubes, rectangular tubes, round tubes, oval tubes, and various profiles.

Our laser equipment is versatile and capable of processing a wide range of both metal and non-metal materials. It also finds applications in various other fields, including plastic processing, craft manufacturing, and automotive production.

Choosing the right laser power is crucial, and it largely depends on your primary application. For tasks like metal engraving, higher laser power is necessary to achieve precise results.

Laser marking is a process where a high-energy density laser is used to selectively irradiate a workpiece, causing the surface material to vaporize or undergo a chemical reaction that changes its color, leaving behind a permanent mark.

Yes, our laser marking machines are equipped with comprehensive safety features and comply with local safety standards and regulations, ensuring safe operation in any environment.

Our lasers are versatile and can be used to cut, mark, or engrave a wide variety of materials, including plastic, wood, rubber, leather, and metals, among others.

The best laser equipment for you depends on what you intend to achieve. Key factors to consider include the type of material you’re processing, the size of the workpiece, and the required laser power.

Shape distortion and cutting overlap can result from several issues, such as loose timing belt screws, disconnected motor wires, motor damage, or a faulty driver. It's important to check these components to troubleshoot the problem.

Our laser machines are designed with advanced, high-precision technology, ensuring consistent performance and accuracy throughout their entire service life