Compared to traditional mechanical and plasma cutting methods, fiber laser cutting machines offer higher speed, a broader cutting range, and a higher degree of automation. Its higher precision and smaller heat-affected zone result in cleaner cuts with minimal material deformation, making it ideal for detailed and high-quality production. We provide professional customized solutions tailored to your specific needs with precision and reliability, and offer comprehensive after-sales service to ensure worry-free operation.

Open flatbed fiber laser cutting machine is an efficient thermal cutting process on metal sheets, offering positioning accuracy up to ±0.03mm, ensuring precise cuts and reducing material waste, and a maximum speed of 80,000mm/min.

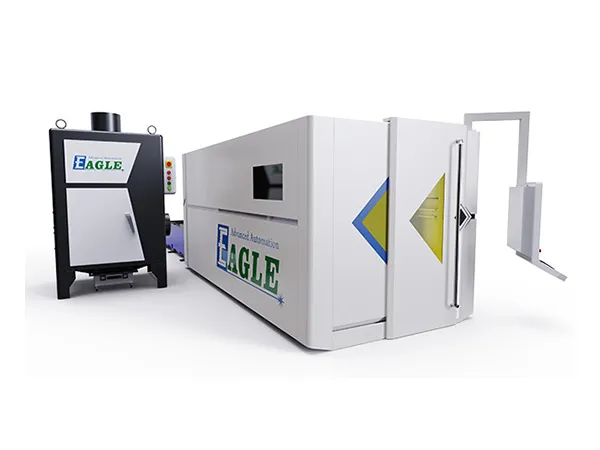

This enclosed flatbed fiber laser cutting machine is specifically designed for high-speed cutting of various sheet metals.

The enclosed flatbed fiber laser cutting machine is designed for high-speed cutting of various metal sheets. It provides a reliable solution for ultra-fast production, meeting the demands of large-format, high-volume, and high-efficiency sheet metal processing.

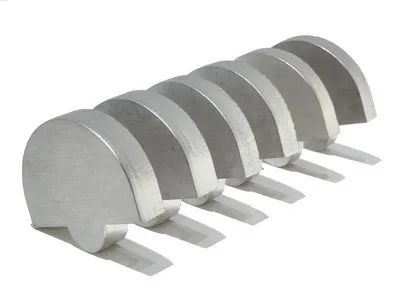

The high precision metal laser cutting machine offers an excellent customized solution for small-format,low-volume, high-precision processing of metal sheets and tubes. It is capable of precisely cutting materials such as carbon steel, stainless steel, tinplate, galvanized sheet, aluminum, and copper.

This laser cutting machine features a dual-drive gantry system with a rail mounted gantry structure delivering high accuracy in large scale projects. The rack and pinion transmission system iscomplemented by a centralized lubrication system that minimizes its downtime and makes maintenance simpler.

Our laser machines are designed with advanced, high-precision technology, ensuring consistent performance and accuracy throughout their entire service life

Laser Tube Cutting Machine

Laser Tube Cutting Machine

Our laser tube cutting system can be equipped with various fiber laser heads, allowing for the precise cutting of aluminum, stainless steel, and carbon steel workpieces.

Fiber Laser Marking Machine

Fiber Laser Marking Machine

Our marking systems are equipped with top-tier lasers, including the MOPA M7 30W fiber laser, capable of marking a wide range of materials such as metal, plastic, glass, ceramics, and wood.

Fiber Laser Welding Machine

Fiber Laser Welding Machine

Laser welding is applicable to a wide range of metals and alloys, including carbon steel, stainless steel, zinc, copper, aluminum, chromium, and precious metals like gold and silver.

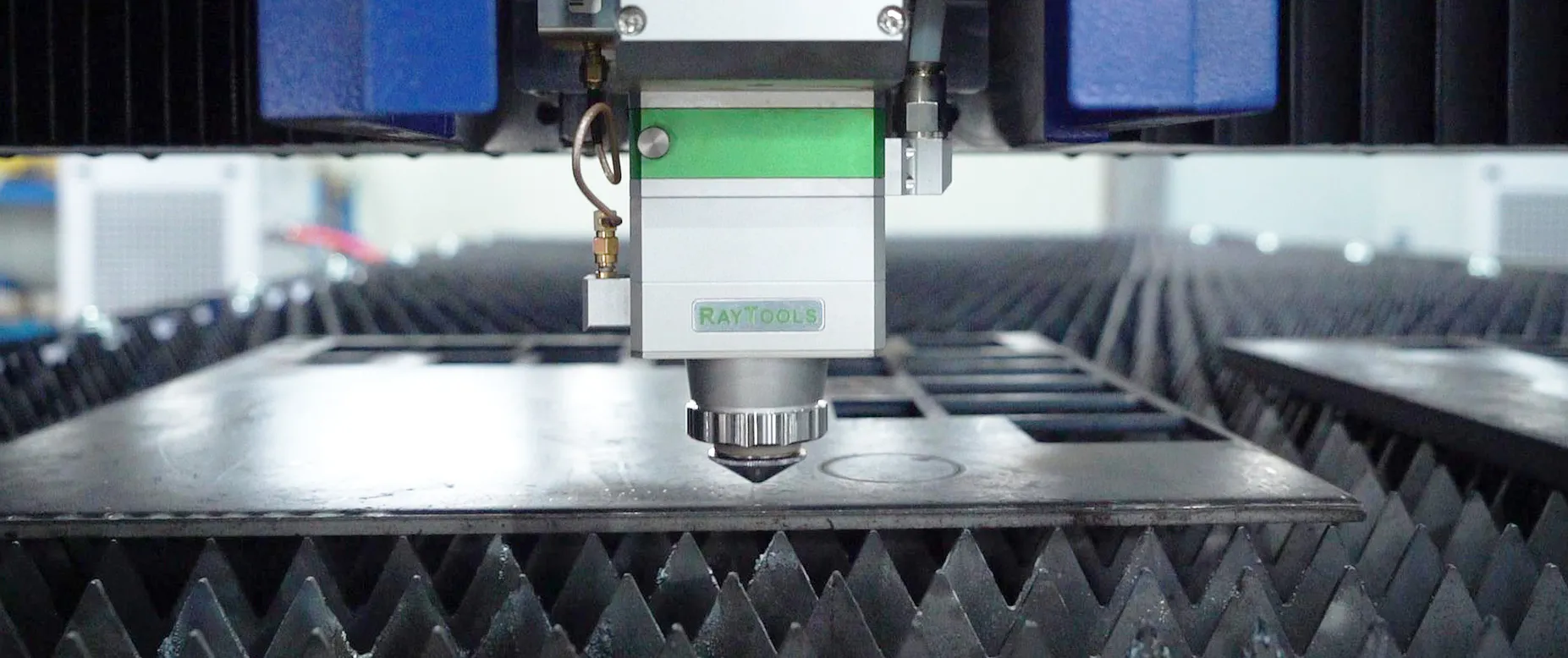

Laser Cutting Machine

Laser Cutting Machine

Our laser cutting systems primarily use two types of laser cutting heads, delivering high precision and speed across a variety of metals such as aluminum, steel, stainless steel, and copper, making them ideal for intricate designs and efficient industrial applications.