The laser machine’s status is easily observed with indicator lights, red during operation and green when stopped.

If the sensor detects a flame, the machine will automatically pause, and the laser will stop emitting. An alarm will be activated, with the red light flashing and the buzzer sounding, until the operator intervenes.

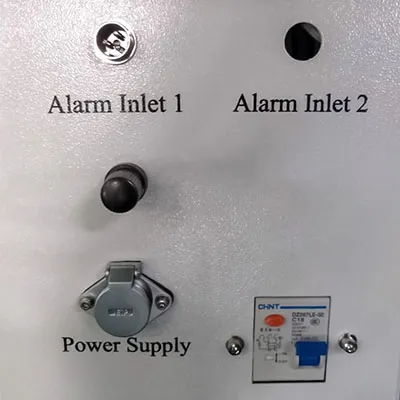

Alarm system instructions:

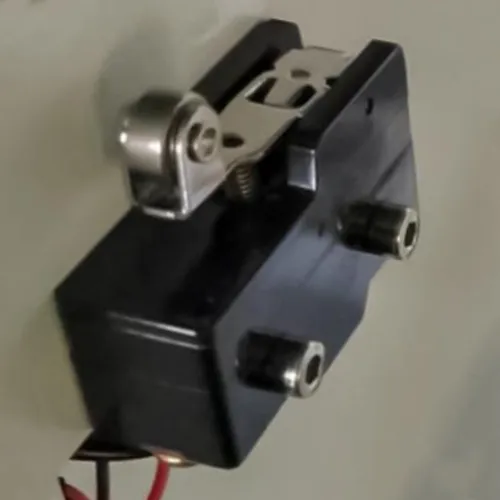

A detailed schematic of the connection between the alarm circuit and the operation indicator is shown below:

Our marking systems are equipped with top-tier lasers, including the MOPA M7 30W fiber laser, capable of marking a wide range of materials such as metal, plastic, glass, ceramics, and wood. These machines can effortlessly engrave patterns, text, barcodes, and other images with high precision.

Laser welding is applicable to a wide range of metals and alloys, including carbon steel, stainless steel, zinc, copper, aluminum, chromium, and precious metals like gold and silver.

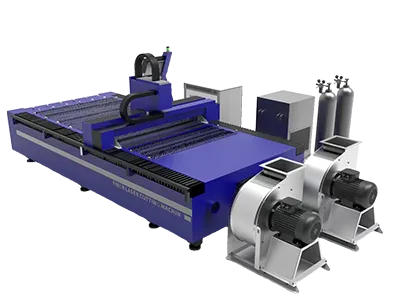

Our laser cutting systems primarily use two types of laser cutting heads, delivering high precision and speed across a variety of metals such as aluminum, steel, stainless steel, and copper, making them ideal for intricate designs and efficient industrial applications.

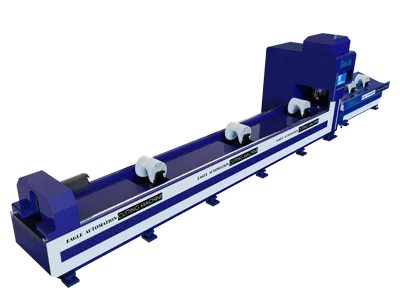

Our laser tube cutting system can be equipped with various fiber laser heads, allowing for the precise cutting of aluminum, stainless steel, and carbon steel workpieces.