We understand that after-sales support is not just an add-on—it's a crucial part of your overall experience with our products. We’ve designed our after-sales services to ensure that your investment continues to deliver value long after the initial purchase. Here’s how we support you:

We know that downtime can be costly. That’s why our repair services are designed to get the laser machine back up and running as quickly as possible. Whether it's an unexpected fault or damage, our technical support team is just a call or click away. We offer both on-site and remote repair services, ensuring that a professional technician can diagnose and fix the issue efficiently. Our goal is to minimize your equipment downtime and keep your operations smooth.

Technology evolves, and so should your equipment. We provide comprehensive upgrade services that keep your laser cutting and processing equipment at the advanced edge. Whether you need a software update to enhance performance, a hardware upgrade for increased capacity, or functional enhancements to stay competitive, we’ve got you covered. We work hand-in-hand with you throughout the upgrade process, ensuring a seamless transition with full post-upgrade training and support. This way, your equipment remains as innovative as your business.

Preventive maintenance is key to extending the life of your laser processing equipment and avoiding costly breakdowns. We offer tailored maintenance plans that include regular inspections, cleaning, lubrication, and parts replacement. Our proactive approach ensures that your machines operate at peak performance, reducing the likelihood of unexpected failures. Choose the maintenance plan that fits your needs, and rest assured that your equipment is in expert hands. Regular maintenance also ensures compliance with industry standards, which is crucial for maintaining certifications and staying competitive.

Empower your team with the knowledge and skills they need to maximize the potential of your laser equipment. Our training services cover everything from basic operation to advanced maintenance and safety protocols. Delivered through online courses, on-site sessions, or comprehensive training videos, our programs are tailored to your specific requirements. With expert guidance, your team will be equipped to handle the equipment efficiently, leading to improved productivity and reduced operational risks.

In today’s fast-paced world, time is of the essence. Our remote support services offer quick and effective solutions through phone, email, or video conferencing. Whether you’re facing a minor issue or need detailed troubleshooting, our experts are ready to assist you in real-time. This service is designed to provide immediate answers and solutions, reducing the need for on-site visits and minimizing any disruption to your workflow.

Access to the right parts when you need them is critical to maintaining continuous operations. We offer a spare parts supply service that ensures you have access to all the components you need. Whether it’s a routine replacement or an emergency repair, you can rely on us to provide high-quality parts that are compatible with your equipment. We understand that every second counts, so we offer flexible procurement options, including bulk orders for cost savings and small orders for immediate needs.

Our marking systems are equipped with top-tier lasers, including the MOPA M7 30W fiber laser, capable of marking a wide range of materials such as metal, plastic, glass, ceramics, and wood. These machines can effortlessly engrave patterns, text, barcodes, and other images with high precision.

Laser welding is applicable to a wide range of metals and alloys, including carbon steel, stainless steel, zinc, copper, aluminum, chromium, and precious metals like gold and silver.

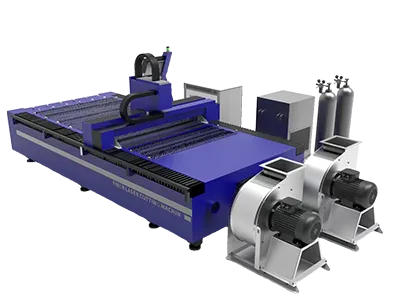

Our laser cutting systems primarily use two types of laser cutting heads, delivering high precision and speed across a variety of metals such as aluminum, steel, stainless steel, and copper, making them ideal for intricate designs and efficient industrial applications.

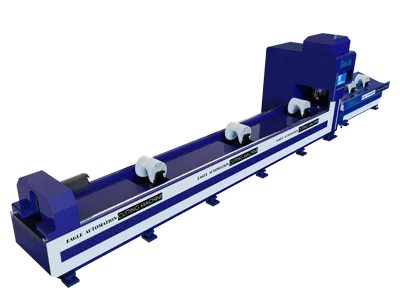

Our laser tube cutting system can be equipped with various fiber laser heads, allowing for the precise cutting of aluminum, stainless steel, and carbon steel workpieces.