This laser marking machine features an integrated design with a compact and small footprint, easy to install and operate, making it an ideal choice for a limited workspace. The fully enclosed cabinet ensures a noise-free operation, creating a safe and quiet working environment. Equipped with a JPT laser source and controlled by EZCAD software, it boasts high photoelectric conversion efficiency, low power consumption, high peak power, and single-pulse energy, all contributing to fast marking speeds.

| Model | FC-MOPA 30 |

| Laser Source | MOPA fiber laser |

| Laser Power | 30W |

| Laser Wavelength | 1064 nm |

| Working Area | 4×4inch / 7×7inch |

| Marking Speed | ≤5000mm/s |

| Min. Line Width | 0.03mm |

| Min. Character | 0.3mm (depending on materials) |

| Marking Depth | ≤1mm (adjustable based on materials) |

| Repeat Accuracy | ±0.002mm |

| Power Supply | Optional: AC220V/50/60Hz |

| Temperature/ Humidity | 0~35℃/10~95% |

| Power Consumption | ≤800W |

| Cooling Method | Air cooling |

The above parameters are based on laboratory testing and may vary under actual operating conditions

The JPT M7 series high-power pulsed fiber laser source operates with a Master Oscillator Power Amplifier (MOPA) configuration, providing precise and efficient marking capabilities.

The galvo scanner head is characterized by high speed, high linearity, high stability, and low thermal drift, ensuring consistent and accurate marking performance.

Yes, our laser marking machines are equipped with comprehensive safety features and comply with local safety standards and regulations.

Our software supports a variety of marking functions, including text, graphics, barcodes, and QR codes. It also offers comprehensive design, editing, import, and export capabilities, making it a reliable tool for all your marking needs.

Our laser machines are designed with advanced, high-precision technology, ensuring consistent performance and accuracy throughout their entire service life

Fiber Laser Welding Machine

Fiber Laser Welding Machine

Laser welding is applicable to a wide range of metals and alloys, including carbon steel, stainless steel, zinc, copper, aluminum, chromium, and precious metals like gold and silver.

Laser Cutting Machine

Laser Cutting Machine

Our laser cutting systems primarily use two types of laser cutting heads, delivering high precision and speed across a variety of metals such as aluminum, steel, stainless steel, and copper, making them ideal for intricate designs and efficient industrial applications.

Laser Tube Cutting Machine

Laser Tube Cutting Machine

Our laser tube cutting system can be equipped with various fiber laser heads, allowing for the precise cutting of aluminum, stainless steel, and carbon steel workpieces.

Fiber Laser Marking Machine

Fiber Laser Marking Machine

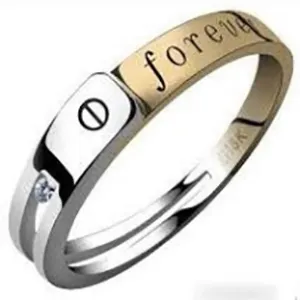

Our marking systems are equipped with top-tier lasers, including the MOPA M7 30W fiber laser, capable of marking a wide range of materials such as metal, plastic, glass, ceramics, and wood.

Our laser systems are capable of processing a wide range of materials, including metals, woods, acrylics, and more. Find the best laser solution to meet your specific needs.