G.U.EAGLE LASER is a reliable supplier of intelligent laser equipment and industrial automation solutions. In order to keep ahead in the laser market, we collaborate with prestigious institutions like Tsinghua University, and top engineering firms like German electromechanical design firms, and American software design companies to continuously push the boundaries of laser technology to offer the most advanced solutions.

Our product lineup includes high-precision laser metal sheet cutting machines, metal marking machines, welding machines, and non-metal cutting machines. We have also established a North American marketing center in Los Angeles, where we are pioneering MR/VR-based laser equipment projects. With a strong international footprint, including our North American marketing center, we are well-positioned to meet the needs of customers worldwide.

Our primary products, such as high-precision laser metal sheet cutting machines, metal marking machines, laser welding machines, and non-metal cutting machines, are widely used across various industrial production and processing fields. We strictly adhere to ISO quality management system standards, ensuring rigorous monitoring and inspection at every stage, from raw material procurement to manufacturing. This meticulous approach guarantees that our products meet the highest standards and customer expectations. Our products have earned a range of international certifications, including CE and ISO system certifications, affirming their quality and safety in compliance with global standards.

In addition to offering standard laser equipment, we excel in providing custom solutions tailored to our customers' specific needs. We can personalize every aspect of our products, from technical specifications and design to functionality, accessories, and after-sales service, ensuring a perfect fit for each unique requirement. Our focus on customization and comprehensive support ensures that every customer receives a solution that perfectly aligns with their business goals.

Our services extend beyond hardware. We are committed to supporting our customers throughout their processing workflows, offering professional guidance to help them make the right choices in production automation. We provide comprehensive services, including pre-sales consultation, technical support, and after-sales service, to deliver superior solutions and complete support. Our team of expert application engineers is available to help design and implement production process controls, while our technical service engineers are always on standby to offer product upgrades, preventive maintenance, and repair services.

Our marking systems are equipped with top-tier lasers, including the MOPA M7 30W fiber laser, capable of marking a wide range of materials such as metal, plastic, glass, ceramics, and wood. These machines can effortlessly engrave patterns, text, barcodes, and other images with high precision.

Laser welding is applicable to a wide range of metals and alloys, including carbon steel, stainless steel, zinc, copper, aluminum, chromium, and precious metals like gold and silver.

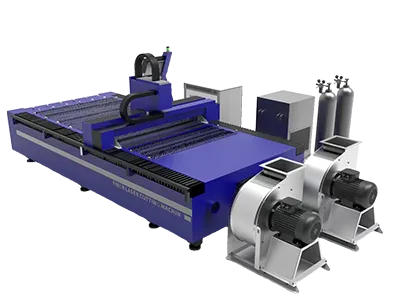

Our laser cutting systems primarily use two types of laser cutting heads, delivering high precision and speed across a variety of metals such as aluminum, steel, stainless steel, and copper, making them ideal for intricate designs and efficient industrial applications.

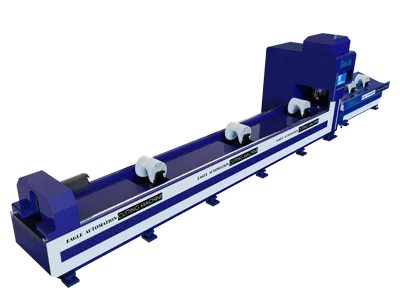

Our laser tube cutting system can be equipped with various fiber laser heads, allowing for the precise cutting of aluminum, stainless steel, and carbon steel workpieces.