Open flatbed fiber laser cutting machine is an efficient thermal cutting process on metal sheets, offering positioning accuracy up to ±0.03mm, ensuring precise cuts and reducing material waste, and a maximum speed of 80,000mm/min. It is equipped with a high-power laser ranging from 6000W to 20000W, a Motovario gear reducer, and a dual-temperature water chiller for consistent performance even during prolonged high-speed operations. These features make it widely applicable in industries such as hardware processing, automotive, shipbuilding, construction machinery, and medical equipment.

| Laser Power | 8000W |

| Working Area | 3000×1500mm |

| Dimensions | 4500×2400×1700mm |

| Positioning Accuracy | ±0.03mm/m |

| Repeatability | ±0.03mm/m |

| Max. Speed | 80000mm/min |

| Max. Acceleration | 1.0G |

| Control System | CypCut |

| Max. Material Loading | 1200kg |

| Phase | 3 |

| Power Supply | 380V/60Hz |

| Weight | 3550kg |

| Item | Quantity | Brand |

| Laser Source | 1 | Maxphotonics (12000W) |

| Laser cutting head | 1 | BOCI |

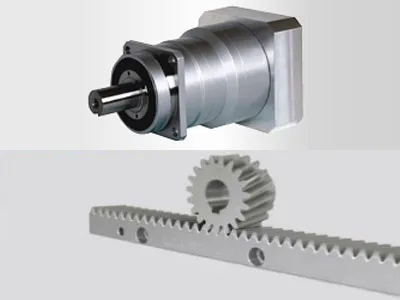

| Gear Reducer (with gear) | 3 | Motovario |

| High Speed Servo Motor | 4 | FUJI |

| High Precision Linear Guide Rail (Tool) | 3 | Hassfull |

| Precision Ball Screw (Z-Axis) | 1 | HIWIN/TBI |

| Precise Rack | 3 | Hassfull |

| Numerical Control System | 1 | CypCut |

| Electric Control | 1 | Schneider |

| Gas Circuit Control | 1 | SMC |

| Water Chiller | 1 | Tongfei |

The high-power continuous wave multimode fiber laser source, available in 6000W to 20000W, features a water-cooled and modular design, ensuring reliable and efficient cutting performance.

We use a linear guide rail gearbox, with the integration of the gearbox and gears during the welding process ensuring high precision in the machine's structural integrity.

The BLT 4 series is a cost-effective and intelligent laser cutting head, designed for 2D, 3D, and bevel cutting applications. It supports slag-free cutting, nozzle cooling, and water-cooled sensors, with lens replacement possible within 5 minutes.

The dual-temperature water chiller provides stable, real-time water temperature control for the laser, with a control accuracy of ±1°C. This system effectively prevents lens damage caused by condensation when using low-temperature water for cooling.

CypCut is a custom software developed specifically for the laser cutting industry. It is powerful yet user-friendly, making it suitable for various processing applications.

The most commonly used auxiliary gases are oxygen and nitrogen. Nitrogen is primarily used for cutting stainless steel, aluminum, and brass, while oxygen is mainly used for cutting carbon steel.

The primary components include the laser head, machine bed, water chiller, control system, air supply system, etc.

Our laser machines are designed with advanced, high-precision technology, ensuring consistent performance and accuracy throughout their entire service life

Laser Tube Cutting Machine

Laser Tube Cutting Machine

Our laser tube cutting system can be equipped with various fiber laser heads, allowing for the precise cutting of aluminum, stainless steel, and carbon steel workpieces.

Fiber Laser Marking Machine

Fiber Laser Marking Machine

Our marking systems are equipped with top-tier lasers, including the MOPA M7 30W fiber laser, capable of marking a wide range of materials such as metal, plastic, glass, ceramics, and wood.

Fiber Laser Welding Machine

Fiber Laser Welding Machine

Laser welding is applicable to a wide range of metals and alloys, including carbon steel, stainless steel, zinc, copper, aluminum, chromium, and precious metals like gold and silver.

Laser Cutting Machine

Laser Cutting Machine

Our laser cutting systems primarily use two types of laser cutting heads, delivering high precision and speed across a variety of metals such as aluminum, steel, stainless steel, and copper, making them ideal for intricate designs and efficient industrial applications.

Our laser systems are capable of processing a wide range of materials, including metals, woods, acrylics, and more. Find the best laser solution to meet your specific needs.