We primarily address the laser processing needs of our global clients, enhancing the ease of use and maintenance of standard laser equipment, and enabling the rapid customization of non-standard products. We specialize in the development of various types of laser systems tailored to your specific requirements.

The custom product processing flow begins with understanding the laser processing requirements of the client, followed by the development of a product workshop process and site and equipment models. We ensure compliance with laser safety standards and provide remote software customization. The process continues with Unity-based VR/MR output, leading to customer installation and acceptance. After installation, we fine-tune software details and offer online processing monitoring to ensure everything operates smoothly and meets the client's expectations.

Our marking systems are equipped with top-tier lasers, including the MOPA M7 30W fiber laser, capable of marking a wide range of materials such as metal, plastic, glass, ceramics, and wood. These machines can effortlessly engrave patterns, text, barcodes, and other images with high precision.

Laser welding is applicable to a wide range of metals and alloys, including carbon steel, stainless steel, zinc, copper, aluminum, chromium, and precious metals like gold and silver.

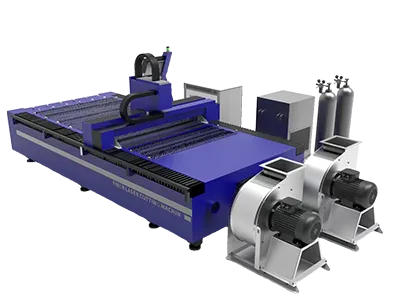

Our laser cutting systems primarily use two types of laser cutting heads, delivering high precision and speed across a variety of metals such as aluminum, steel, stainless steel, and copper, making them ideal for intricate designs and efficient industrial applications.

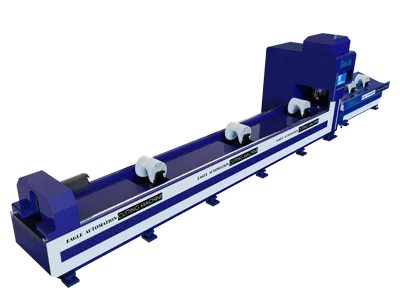

Our laser tube cutting system can be equipped with various fiber laser heads, allowing for the precise cutting of aluminum, stainless steel, and carbon steel workpieces.