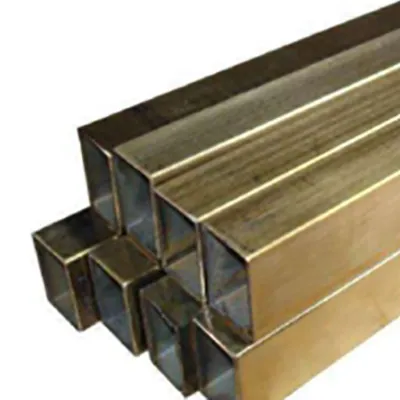

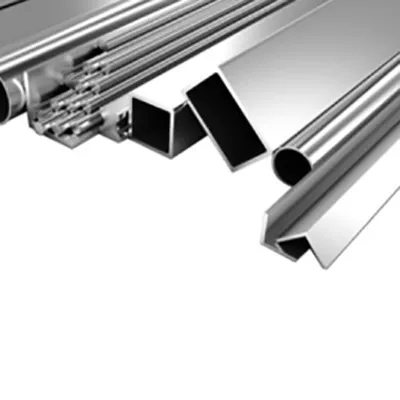

The two-chuck laser cutting machine is a versatile tool for different metal working industries, designed for cutting and drilling square tubes, rectangular tubes, round tubes, oval tubes, and various profiles. It is widely used in industries such as kitchenware, lighting, automotive, fitness equipment, hardware, and other sectors that require metal processing and tube cutting equipment. The laser power ranges from 1000W to 6000W and is equipped with high-precision digital chucks. The machine can handle single tubes weighing up to 400kg, making it ideal for cutting stainless steel, carbon steel, galvanized pipes, copper pipes, aluminum pipes, aluminum alloys, and other metal materials with ease and precision.

| Standard | ||

| Item | Quantity | Brand |

| Laser | 1 | Raycus |

| Laser cutting head | 1 | BOCI |

| Reducer (Including Gears) | 1 | TECHMECH |

| Fast Speed Servo Motor | 5 | INOVANCE |

| A Drive System (Rack and Pinion) | 1 | YYC |

| B Drive System (Linear Guide) | 1 | AIRTAC |

| Numerical Control System | 1 | Cypcut |

| Precise Rack | 3 | Hassfull |

| Water Chiller | 1 | Hanli |

| Industrial Air Conditioning System | 1 | Hanli |

| Optional | ||

| Item | Quantity | Brand |

| Air Compressor | 1 | GUeagle |

| Stabilizer | 1 | GUeagle |

| Dust Removal System | 1 | GUeagle |

| Automatic Programming Nesting Software | 1 | GUeagle |

| Air Extraction System | 1 | GUeagle |

| Laser Power | 6000W |

| Dimension | 23000×3450×2500mm |

| Phase | 3 |

| Rated Voltage/Frequency | 380V/60Hz |

| Protection Level | IP54 |

| Max. Finished Tube Length | 12000mm |

| Linear Axis Positioning Accuracy | 0.05mm/m (VDI/DGQ3441) |

| Repeatability | ±0.03mm |

| Cutting Size (Square/Rectangular Tube) |

Square tube: 10×10-280×280mm Rectangular tube: length 10-280mm, width 10-280mm |

| Max. Rotation Speed of Axis | 110rpm |

| Max. Speed | 100m/min |

| Max. Load Weight of Chuck | 400kg |

| Machine Weight | 15000kg |

The 6000W global series continuous-wave fiber laser offers high electro-optical conversion efficiency, excellent beam quality, high energy density, a wide modulation frequency range, with minimal maintenance.

The BLT 4 series is a cost-effective smart cutting head, designed specifically for 2D, 3D, and bevel cutting. It ensures stable cutting performance, is easy to install and set up, and delivers outstanding results.

This is a versatile laser machine that is not only capable of cutting and piercing round tubes but can also process square tubes, rectangular tubes, oval tubes, and various profiles.

The machine has a repositioning accuracy of ±0.03mm, ensuring that it almost perfectly aligns with the original position, maintaining a very high level of precision.

Our laser machines are designed with advanced, high-precision technology, ensuring consistent performance and accuracy throughout their entire service life

Fiber Laser Marking Machine

Fiber Laser Marking Machine

Our marking systems are equipped with top-tier lasers, including the MOPA M7 30W fiber laser, capable of marking a wide range of materials such as metal, plastic, glass, ceramics, and wood.

Fiber Laser Welding Machine

Fiber Laser Welding Machine

Laser welding is applicable to a wide range of metals and alloys, including carbon steel, stainless steel, zinc, copper, aluminum, chromium, and precious metals like gold and silver.

Laser Cutting Machine

Laser Cutting Machine

Our laser cutting systems primarily use two types of laser cutting heads, delivering high precision and speed across a variety of metals such as aluminum, steel, stainless steel, and copper, making them ideal for intricate designs and efficient industrial applications.

Laser Tube Cutting Machine

Laser Tube Cutting Machine

Our laser tube cutting system can be equipped with various fiber laser heads, allowing for the precise cutting of aluminum, stainless steel, and carbon steel workpieces.

Our laser systems are capable of processing a wide range of materials, including metals, woods, acrylics, and more. Find the best laser solution to meet your specific needs.