Throughout the laser machine production process, we implement rigorous quality control measures to ensure that our products meet the established quality standards and specifications. This includes inspections and testing at every stage of production, as well as regular maintenance and adjustments of production equipment to maintain process stability and efficiency.

Our marking systems are equipped with top-tier lasers, including the MOPA M7 30W fiber laser, capable of marking a wide range of materials such as metal, plastic, glass, ceramics, and wood. These machines can effortlessly engrave patterns, text, barcodes, and other images with high precision.

Laser welding is applicable to a wide range of metals and alloys, including carbon steel, stainless steel, zinc, copper, aluminum, chromium, and precious metals like gold and silver.

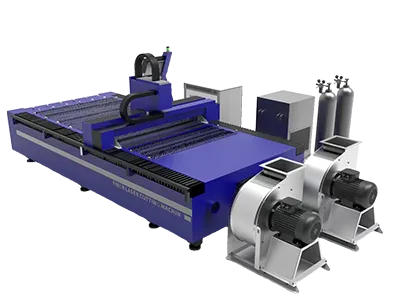

Our laser cutting systems primarily use two types of laser cutting heads, delivering high precision and speed across a variety of metals such as aluminum, steel, stainless steel, and copper, making them ideal for intricate designs and efficient industrial applications.

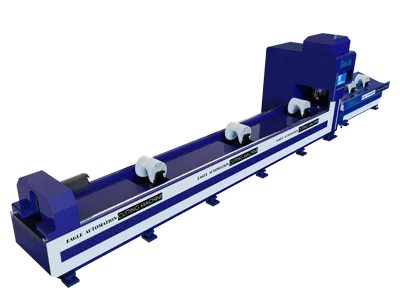

Our laser tube cutting system can be equipped with various fiber laser heads, allowing for the precise cutting of aluminum, stainless steel, and carbon steel workpieces.